Often it is necessary to add a coating to an AFM cantilever. In most cases it is a reflex coating on the backside of the cantilever to enhance the reflection of the laser to get a sufficient signal into the AFM photodetector.

Unfortunately, adding a coating to a cantilever has several drawbacks such as:

- a coating adds stress to the cantilever

- when the cantilever is illuminated with the laser the so called Bimorph-Effect (if operating in liquids) will bend the cantilever and let the laser drift out of the photo-detector (thermal drift)

- a higher damping of the cantilever which leads to a lower Q-factor

- a higher noise of the cantilever

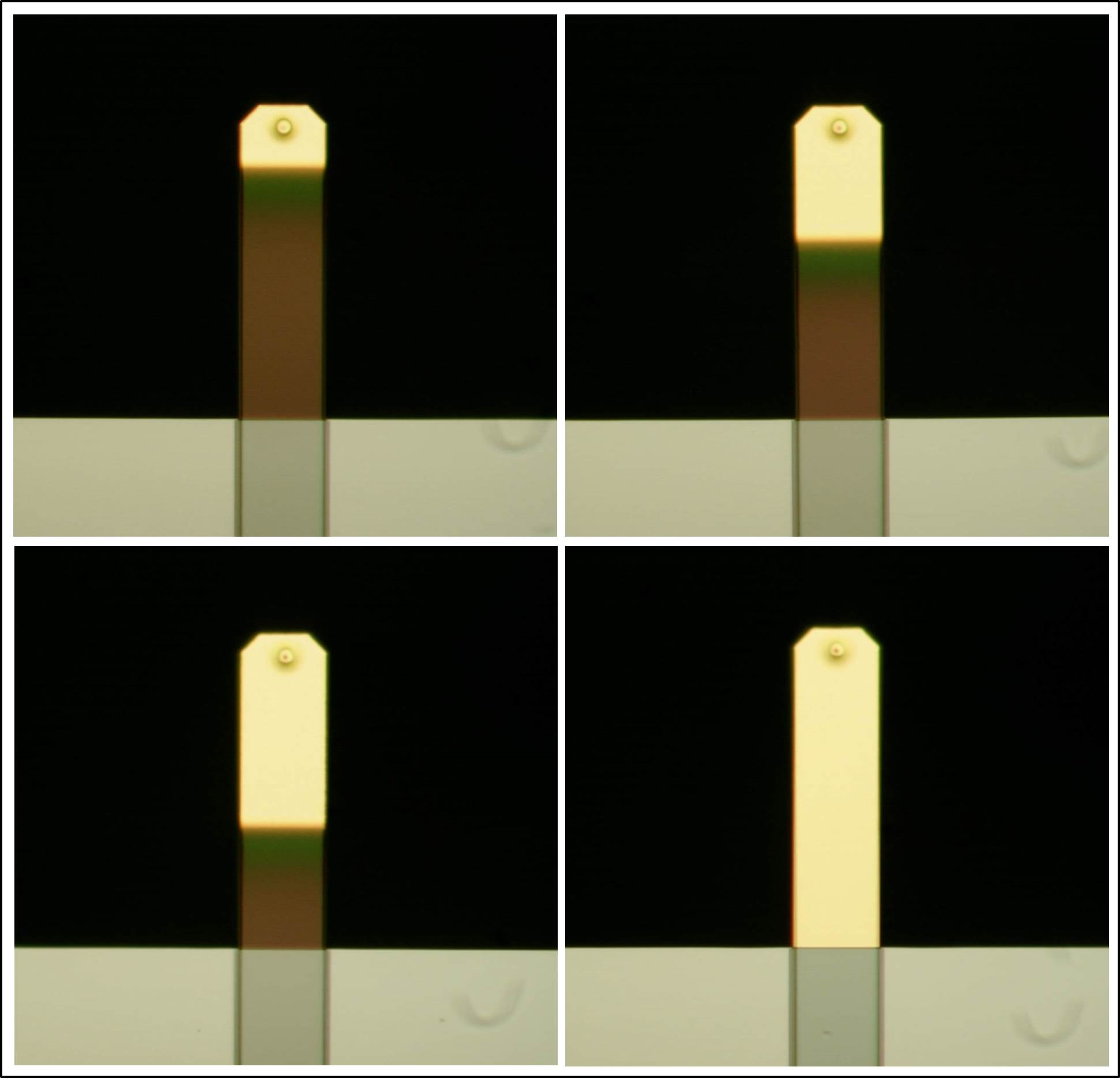

Those effects can be reduced dramatically when the coating is not done on the whole cantilever, but only on a part of it. The images above are showing cantilevers with a reflex coating covering about 20, 40, 65 and 100% of the cantilever.

To provide best quality with highest possible cantilever sensitivity NANOSENSORS™ manufactures their Uniqprobe® cantilever as the only AFM tip exclusively with a partial coating!

To learn more, please have a look at