Lately the production of nanocrystalline magnetic materials starting with coarse grained materials (top-down approach) has received increasing interest.*

The advantage of the top-down approach compared to the bottom-up approach ( e.g. using melt spinning, stacking of sheets, annealing treatments and other processing steps) is that rare-earth elements and additional processing steps such as stacking of sheets are not necessary.*

In the article “On the magnetic nanostructure of a Co–Cu alloy processed by high-pressure torsion” Martin Stückler, Christian Teichert, Aleksandar Matković, Heinz Krenn, Lukas Weissitsch, Stefan Wurster, Reinhard Pippan, Andrea Bachmaier present a preparation route of Co–Cu alloys with soft magnetic properties by high-pressure torsion deformation. Nanocrystalline, supersaturated single-phase microstructures are obtained after deformation of Co–Cu alloys, which are prepared from an initial powder mixture with Co-contents above 70 wt.%.*

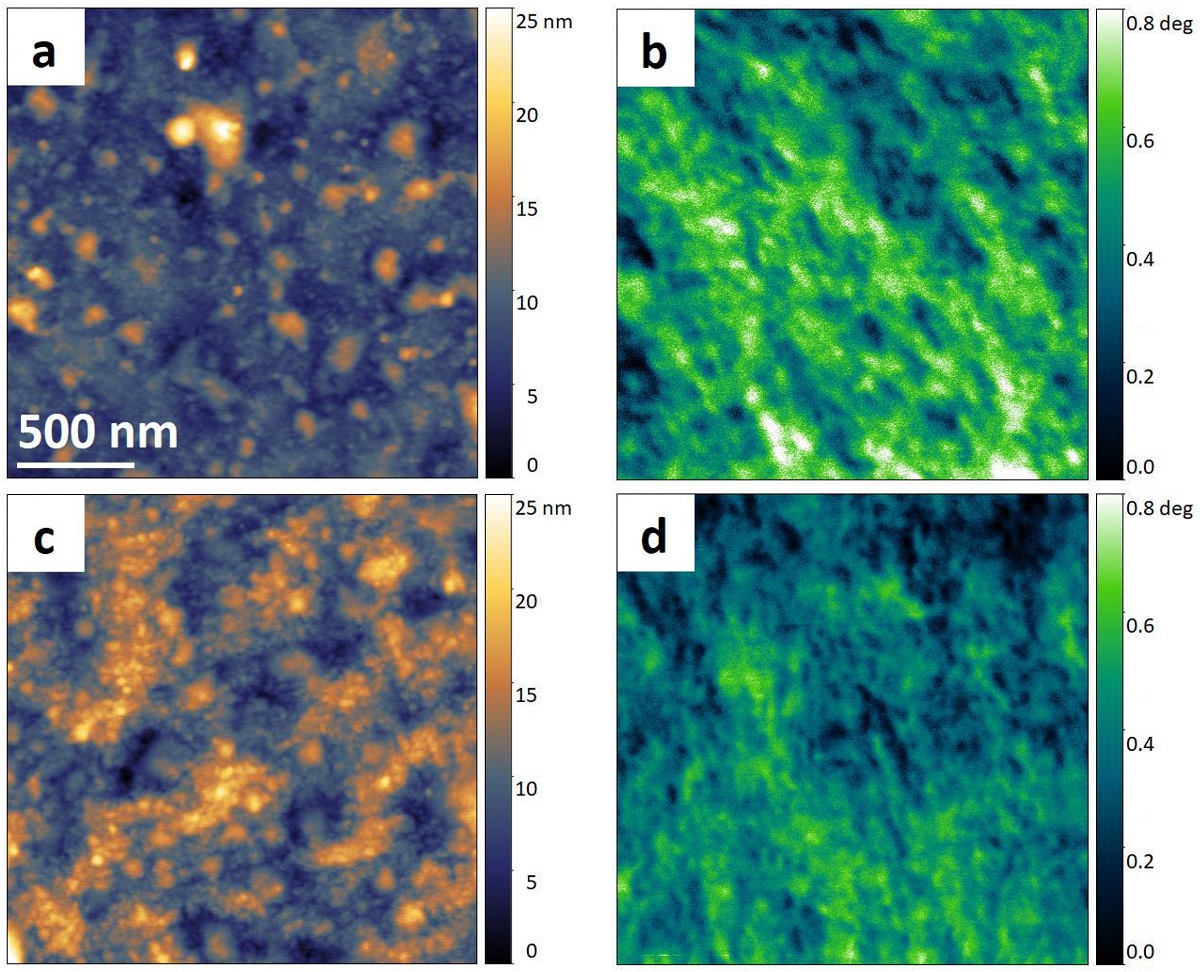

The authors used NANOSENSORS SSS-MFMR magnetic AFM probes optimized for high resolution magnetic force imaging in the quantitative analysis of the magnetic microstructure by magnetic force microscopy to understand the measured magnetic properties and correlated this to the detected changes in coercivity.

The achieved results by Martin Stückler et al. show that the rising coercivity can be explained by a magnetic hardening effect occurring in context with spinodal decomposition.*

2 μm × 2 μm AFM scans of (a) as-deformed state and (c) 300 °C annealed state. The corresponding MFM scans of the as-deformed and 300 °C annealed state are shown in (b) and (d) respectively. The axial direction of the HPT specimen points out of the plane, the shear direction is in horizontal direction. The lateral scale bar in (a) applies to all scans. The minimum height and phase signal values are shifted to zero for visualization purposes.

*Martin Stückler, Christian Teichert, Aleksandar Matković, Heinz Krenn, Lukas Weissitsch, Stefan Wurster, Reinhard Pippan, Andrea Bachmaier

On the magnetic nanostructure of a Co–Cu alloy processed by high-pressure torsion

Journal of Science: Advanced Materials and Devices, Volume 6, Issue 1, March 2021, Pages 33-41

DOI: https://doi.org/10.1016/j.jsamd.2020.09.013

Please follow this external link to read the full article: https://www.sciencedirect.com/science/article/pii/S2468217920300873?via%3Dihub

Open Access The article “On the magnetic nanostructure of a Co–Cu alloy processed by high-pressure torsion” by Martin Stückler, Christian Teichert, Aleksandar Matković, Heinz Krenn, Lukas Weissitsch, Stefan Wurster, Reinhard Pippan, Andrea Bachmaier is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.