Zeno Schumacher, Yoichi Miyahara and Peter Grütter from McGill University, Montreal together with our colleague Laure Aeschimann from NANOSENSORS™ are showing in their current publication “Improved atomic force microscopy cantilever performance by partial reflective coating” (Beilstein J. Nanotechnol. 2015, 6, 1450–1456) the advantages of partially coated AFM cantilevers.

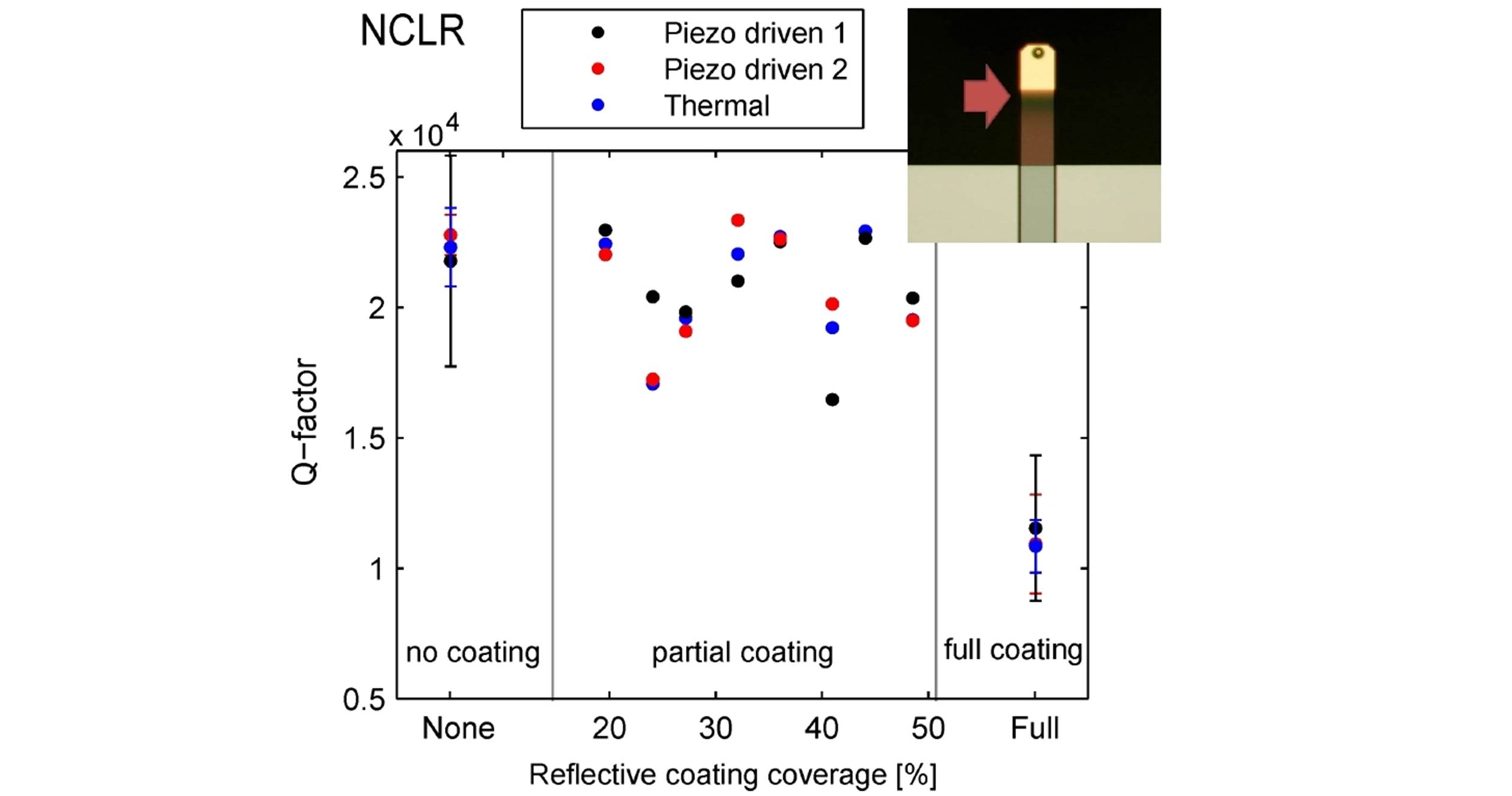

Q-factors of NCLR cantilevers with different coating coverage percentages measured in high vacuum. From: Beilstein J. Nanotechnol. 2015, 6, 1450–1456.

They coated cantilevers with coating coverages from 15 to 100% and measured low-frequency noise and Q-factors. In the graph above shows the Q-factors of NCLR cantilevers with different coating coverage percentages measured in high vacuum. A 30 nm Al coating was added to a 7 μm thick NANOSENSORS™ NCLR cantilever. Adding a complete reflective coating to the cantilever will reduce the Q-factor by half compared to the uncoated cantilevers. By minimizing the coating to 20% of the cantilever length the same Q-factor as that of the uncoated cantilever can be achieved.

The original article can be found on the Beilstein Journal of Nanotechnology website