Yutaro Katsuyama, Shunske Kayukawa, Tomoharu Tokunaga, Shunsuke Kobayashi, Shigekazu Hidaka, Atsutomo Nakamura and Takahisa Yamamoto

Variation of (001) surface structures of strontium titanate single crystals caused by flash event under direct/alternative current electric fields

Ceramics International, Volume 50, Issue 19, Part C, 1 October 2024, Pages 37366-37372

DOI: https://doi.org/10.1016/j.ceramint.2024.05.055

Yutaro Katsuyama, Ayu Kodaira, Tomoharu Tokunaga and Takahisa Yamamoto

Scanning electron microscopy observation in wide field of view for SrO/TiO2-terminated step-terrace structure formed on SrTiO3(001) single crystal surface

Journal of the Ceramic Society (2023) volume 131, issue 5, p. 135-139

DOI: https://doi.org/10.2109/jcersj2.23011

Devendra Pareek, Marco A. Gonzalez, Nedal Grewo, Marten L. Janßen, Kumarahgiri Arunakiri, Kayode Luqman Alimi, Martin Silies, Jürgen Parisi, Levent Gütay and Sascha Schäfer

Large-Area Growth of MoS2/WS2 Heterostructures by a Sequential Atomic Layer Deposition and Spin-Coating Approach

Advanced Materials Interfaces, Volume 9, Issue 31, November 3, 2022, 2200816

DOI: https://doi.org/10.1002/admi.202200816

Gaoliang Dai, Xiukun Hu, Julian Hering, Matthias Eifler, Jörg Seewig and Georg von Freymann

Define and measure the dimensional accuracy of two-photon laser lithography based on its instrument transfer function

Journal of Physics: Photonics, 2021, Volume 3, Number 3 034002

DOI: https://doi.org/10.1088/2515-7647/abfaa7

Martyn Sozanskyi, Vitalii Stadnik, Pavlo Shapoval, Iosyp Yatchyshyn, Ruslana Guminilovych, Stepan Shapoval

Optimization of Synthesis Conditions of Mercury Selenide Thin Films

Chemistry & Chemical Technology, 2020, Vo. 14, No 3, pp. 290 – 296

DOI: https://doi.org/10.23939/chcht14.03.290

Davood Momeni Pakdehi, Philip Schädlich, Thi Thuy Nhung Nguyen, Alexei A. Zakharov, Stefan Wundrack, Emad Najafidehaghani, Florian Speck, Klaus Pierz, Thomas Seyller, Christoph Tegenkamp, Hans Werner Schumacher

Silicon Carbide Stacking-Order-Induced Doping Variation in Epitaxial Graphene

Advanced Functional Materials, Volume 30, Issue 45, November 4, 2020, 2004695

DOI: https://doi.org/10.1002/adfm.202004695

Elżbieta U. Stolarczyk, Katarzyna Sidoryk, Marcin Cybulski, Marek Kubiszewski and Krzysztof Stolarczyk

Design of Therapeutic Self-Assembled Monolayers of Thiolated Abiraterone

Nanomaterials 2018, 8(12), 1018

DOI: https://doi.org/10.3390/nano8121018

J Jakubowicz, G Adamek and M Sopata

Characterization of High-Energy Ball-Milled and Hot-Pressed Nanocrystalline Tantalum

IOP Conference Series: Materials Science and Engineering, Volume 216, The 2nd International Conference on Civil Engineering and Materials Science 26–28 May 2017, Seoul, Korea

DOI: https://doi.org/10.1088/1757-899X/216/1/012006

J Jakubowcz, G Adamek, M Sopata, J K Kope and P Siwak

Hot pressing of nanocrystalline tantalum using high frequency induction heating and pulse plasma sintering

IOP Conference Series: Materials Science and Engineering, Volume 283, 6th Global Conference on Materials Science and Engineering 24–27 October 2017, Beijing, China, 283 012001

DOI: https://doi.org/10.1088/1757-899X/283/1/012001

TaskinTuna, Martin Wein, Michael Swain, Jens Fischer, Wael Att

Influence of ultraviolet photofunctionalization on the surface characteristics of zirconia-based dental implant materials

Dental Materials, Volume 31, Issue 2, February 2015, Pages e14-e24

DOI: https://doi.org/10.1016/j.dental.2014.10.008

D. Bergmann, B. Bodermann, H. Bosse, E. Buhr, G. Dai, R. Dixson, W. Häßler-Grohne, K. Hahm, and M. Wurm

Photomask linewidth comparison by PTB and NIST

Proceedings Volume 9636, Scanning Microscopies 2015; 96360S (2015) (2 November 2015); Event: SPIE Scanning Microscopies, 2015, Monterey, California, United States

DOI: https://doi.org/10.1117/12.2199453

Katharina J. Jetzschmann, Gyula Jágerszki, Decha Dechtrirat, Aysu Yarman, Nenad Gajovic-Eichelmann, Hans-Detlev Gilsing, Burkhard Schulz, Róbert E. Gyurcsányi and Frieder W. Scheller

Vectorially Imprinted Hybrid Nanofilm for Acetylcholinesterase Recognition

Advanced Functional Materials, Volume 25, Issue 32, August 26, 2015, Pages 5178-5183

DOI: https://doi.org/10.1002/adfm.201501900

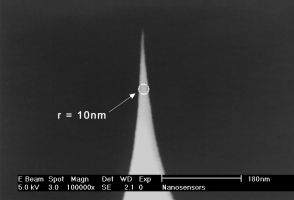

Due to their unique geometry the tips of the are more susceptible to tip damage by electrostatic discharge (ESD) than other Silicon-SPM-Probes.

Due to their unique geometry the tips of the are more susceptible to tip damage by electrostatic discharge (ESD) than other Silicon-SPM-Probes.